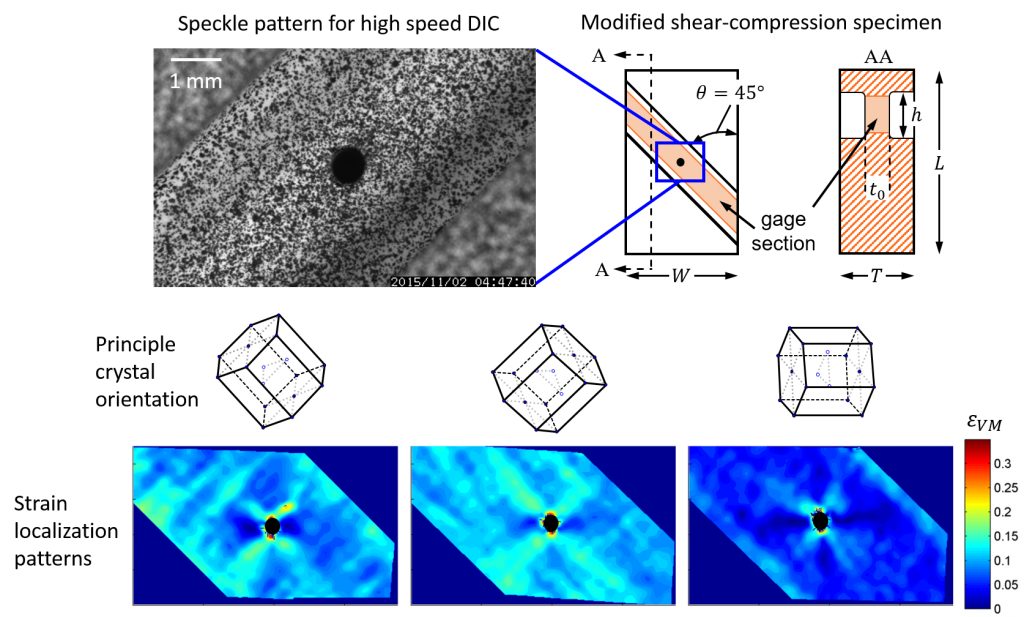

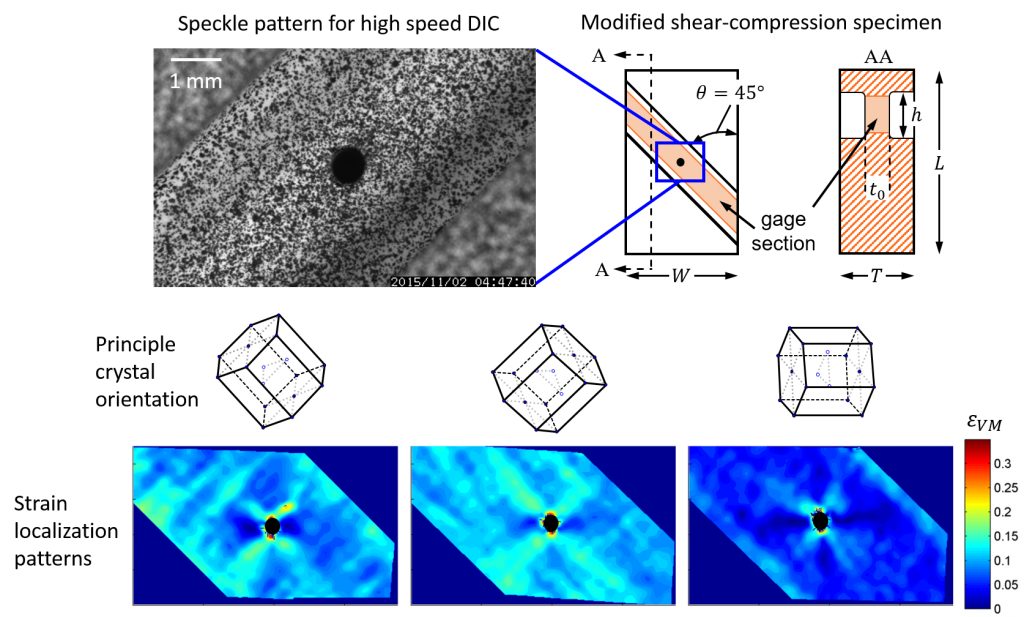

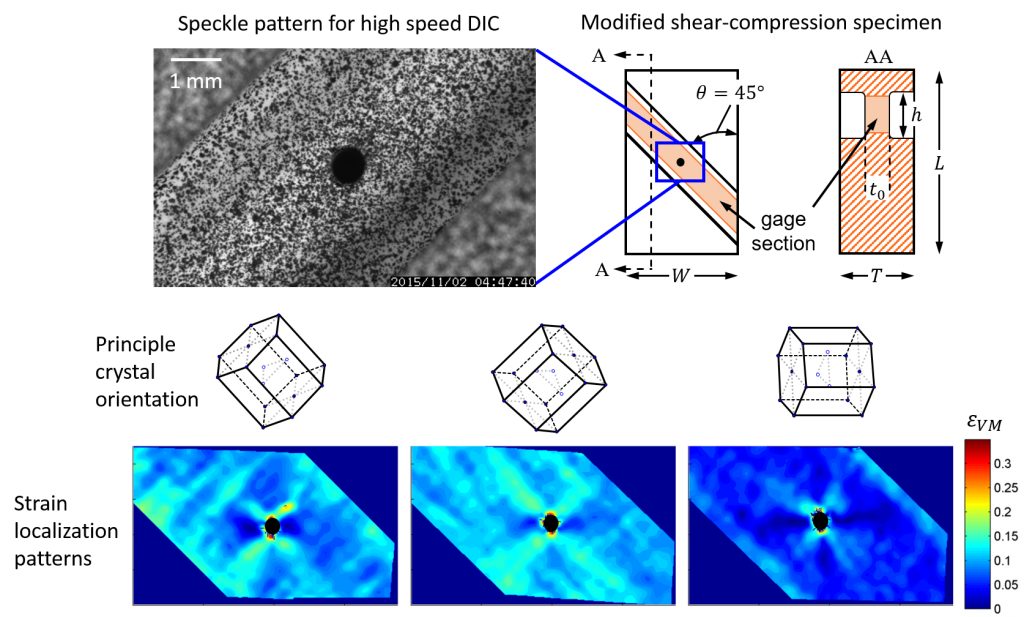

Strain Localization Evolution and Failure

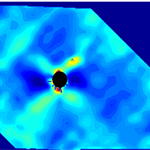

High speed imaging is combined with high strain rate loading to probe the evolution of strain localization leading up to failure in Mg alloys. From this study pathways for deformation are identified which lead to undesired shear band formation and crack formation. Show below is a comparison of the strain localization that occurs at a machined defect for three different loading orientations. The left two strain maps demonstrate the ability of two loading orientations to accommodate deformation in regions away from the specimen through hole. The strain map on the right shows strong localization near the machined defect which leads to the formation of undesirable cracking.